Guangdong moving up digital textile chain

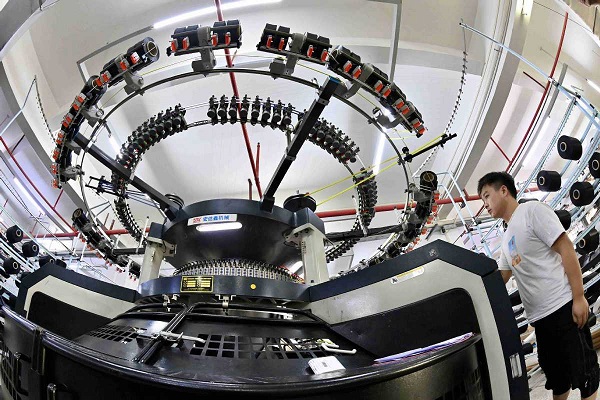

A worker operates a textile machine in Shantou, Guangdong province, in July. [Photo provided to China Daily]

South China's Guangdong province, a powerhouse in textiles, is spreading a digital revolution that promises to transform the industry as it grapples with limitations in global high-end value and supply chains and has little say in setting the industry's international rules and standards.

"There are some 530 ISO (International Organization for Standardization) standards in the textile industry worldwide, of which only 37 are led by China," said Li Lingshen, vice-president of the China Textile Industry Federation.

"This means that in terms of ISO standards, we are responsible for only 7 percent, showing that we don't have much of a say in the formulation of international rules."

Facing such a disparity, Guangdong is committed to bridging the gap through technological prowess. This resolve has sparked a wave of digital initiatives aimed at revolutionizing industrial processes and organizational frameworks.

At the forefront of this digital revolution is Guangzhou Zhijing Information Technology Co, a pioneering force in harnessing digital technologies to streamline textile operations.

"From smart clothing design platforms that slash design times from weeks to minutes to fully automated fabric inspection systems that ensure unparalleled quality, our company aims to empower small and medium-sized enterprises to embrace digitalization and drive efficiency across the textile and garment production industry," said Li Yaping, co-founder and senior vice-president of GZIT.

Utilizing technologies, the company has developed multiple smart cloud platforms covering the entire chain of textile and garment production, procurement, design and sales.

"The days of navigating fabric markets for days on end are a thing of the past thanks to the smart fabric sourcing platform developed by GZIT," said Shi Daqing, general manager of Guangdong Gongying Clothing Co. "With this new technology, fabric selection has been streamlined to a matter of minutes."

In fact, the impact of this digital transformation extends far beyond its borders. Data from GZIT showed that since its establishment, the company has provided digital empowerment services to over 50,000 textile and garment enterprises nationwide, driving the integration of manufacturing and the internet and propelling industries into the future.

Impressed by the digital monitors supplied by GZIT, Chen Kai, general manager of Foshan Xinwei Knitting Co, said, "The operation of equipment in real-time can reduce abnormal downtime of factory equipment by 35 percent and improve overall efficiency by 30 percent."

Wei Jianzhang, vice-president of the Belt and Road Initiative's International Cooperation and Development Research Institute in Shenzhen, Guangdong province, said the changes in the textile industry are just part of Guangdong's broader efforts to forge ahead with its digital agenda and cultivate a thriving ecosystem of industrial internet platform companies and service providers.

"The vision is clear. We must not only serve upstream and downstream enterprises, but also bridge them together, creating a more resilient and competitive industrial chain," Wei said. In an era defined by technological innovation, "Guangdong's digital transformation is not just a step forward — it's a leap into a brighter, more connected future".

All rights reserved. Presented by China Daily